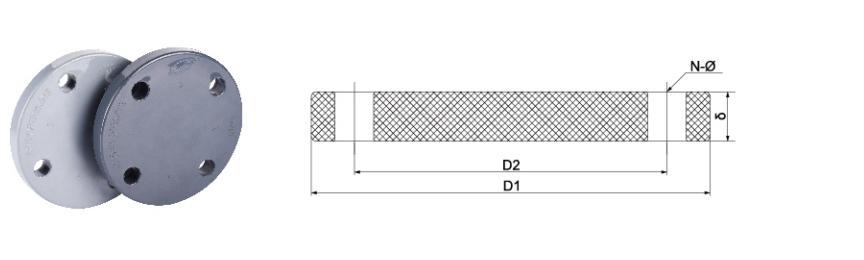

Installation specifications and sealing precautions for UPVC/CPVC blind flanges

UPVC (unplasticized polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride) blind flanges are widely used in many industries due to their excellent corrosion resistance, lightweight and high cost performance, including safe drinking water, metallurgy, photovoltaics, nuclear power, electronic semiconductors, medicine, industrial water treatment, industrial wastewater and other fields. To ensure its long-term stable operation, installation and sealing are crucial. The following are key specifications and precautions:

1. Installation specifications

Flange alignment and tightening

Before installation, check whether the flange surface is flat to avoid stress concentration due to misalignment.

Gradually tighten the bolts in a diagonal order (it is recommended to use stainless steel or corrosion-resistant bolts) to avoid uneven force on one side and affect the sealing.

Gasket selection

Select suitable gaskets (such as EPDM, PTFE or rubber gaskets) according to different media, for example:

Safe drinking water/pharmaceutical industry: must comply with FDA or sanitary standards (such as EPDM).

Industrial wastewater/metallurgical industry: PTFE gaskets that are resistant to acid and alkali corrosion are more suitable.

Temperature and pressure adaptation

UPVC temperature range (0°C~60°C), CPVC can withstand higher temperatures (-40°C~93°C), and materials must be strictly distinguished in scenarios such as photovoltaics (cooling systems) or nuclear power (auxiliary pipelines).

Avoid overpressure use, especially in high-purity water systems in the electronic semiconductor industry, where pressure fluctuations may cause flange deformation.

Support and shockproof

Long pipeline systems (such as industrial water treatment plants) require additional brackets to reduce the vibration load of blind flanges.

2. Sealing precautions

Surface cleaning

Thoroughly clean the flange sealing surface and the inner wall of the pipeline before installation to prevent particulate matter (such as metal debris in the metallurgical industry) from affecting the sealing effect.

Avoid over-tightening

UPVC/CPVC materials have low hardness. Over-tightening of bolts may cause flange cracking, especially in low-temperature environments (such as photovoltaic plant cooling systems).

Media compatibility check

The pharmaceutical/electronic semiconductor industry needs to ensure that the blind flange material does not release harmful substances (such as plasticizers).

In industrial wastewater treatment, it is necessary to resist chemical corrosion such as chlorine and sulfide.

Regular maintenance

In nuclear power or highly dangerous fluid systems, it is recommended to check the flange sealing status regularly to prevent sudden leakage.

3. Key points of industry application

Safe drinking water/pharmaceuticals: give priority to sanitary CPVC flanges to avoid biological contamination.

Photovoltaics/electronic semiconductors: pay attention to the aging effect of thermal cycles on sealing gaskets.

Metallurgy/industrial wastewater: strengthen chemical corrosion resistance design, such as thickened flanges or anti-corrosion coatings.

+86-15258772971

+86-15258772971

dinys009@163.com

dinys009@163.com